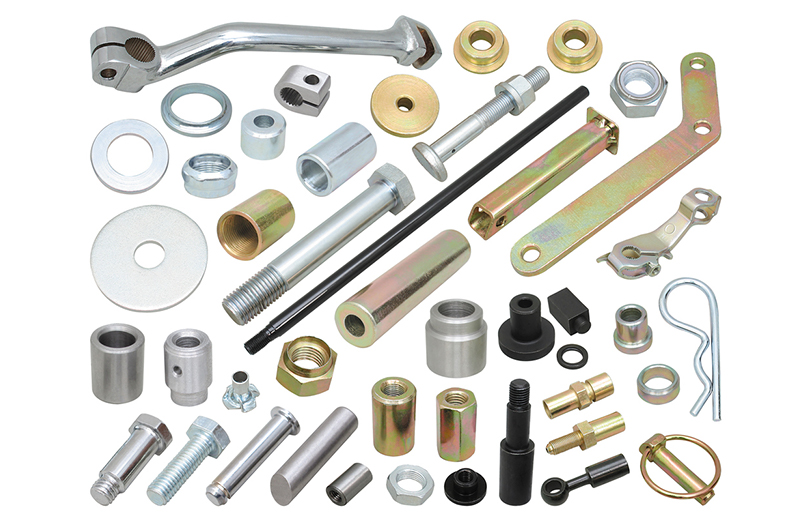

Raw Material

What is powder metallurgy?

Powder metallurgy is a processing method for making various products by using metal powder as a raw material, pressing and sintering. The powder metallurgy process consists of three main steps.

First, the main material is decomposed into a large number of fine particles of powder; then, the powder is placed in a mold cavity and a certain pressure is applied to form a powder blank having the desired part. Finally, the powder blank is sintered. Further processing is carried out for the needs of individual parts.

Products Characteristic - Raw material

Copper

CopperFor general parts. Such as hardware, steam locomotives, sports equipment, information machines, hand tools, home appliances, etc.

Iron

IronSuitable for low noise and medium-high-strength lubrication slides and locks.

Stainless

StainlessSuitable for high strength, high ductility and corrosion-free applications. Such as food machinery.

Copper-iron

Copper-ironalloy

It is suitable for reducing the cost of bronze workpieces and changing materials with different ratios of copper to iron.